silvia

Joined: 10 Oct 2021

Posts: 264

Location: UK

|

Posted: Jul 02, 2025 16:59 Post subject: Uraninite on The Alligator Posted: Jul 02, 2025 16:59 Post subject: Uraninite on The Alligator |

|

|

Uraninite on the Alligator

A brief look at the el Sherana Uranium Mine

Introduction

El Sherana, though a minor Uranium producer by current world standards, was one of the richest Uranium deposits in the world, and its discovery, like the chemical element Uranium, attracted much public interest and admiration. Little known to many mineral collectors of the modern era is the fact that the mine produced world-class specimens of Uraninite, meta-Torbernite and Rutherfordine. Many specimens of Uraninite recovered at the mine also contained visible Native Gold. Though the mine is no longer active, the El Sherana leases still host significant economic reserves of Uranium, Gold and Platinum. The site was placed on care and maintenance towards the end of 1964 and it is now part of a national park called kakadu. The mine’s name is derived from a combination of the names of the daughters (Elvira, Sherryl & Lana) of William Halpin Kay a senior UUNL staff member.

Regrettably there are very few collector quality examples of any of El Sherana’s abundant primary and secondary Uranium minerals to be seen in modern era private or public mineral collections.

DISCOVERY

A team of prospectors led by Joe Fischer discovered the El Sherana Uranium deposit in 1954 following a low level aerial scintillometer survey in the South Alligator Valley region of the Northern Territory. The mine operated from 1954 to 1964 under the ownership of the United Uranium No Liability Company (UUNL) a subsidiary of the Northern Uranium Development Company. The Northern Uranium Development Company was a syndicate of private investors based in Melbourne (Australia).

LOCATION

The mine is located about 214 kilometers (as the crow flies) south–east of Darwin. Travel south from Darwin along the Stuart Highway to Pine Creek a distance of about 210 kilometers. Then travel north-east along the Kakadu highway (A21) for about 63 kilometers and turn right onto Gimbat Road and travel a further 28 kilometers to the mine. The old El Sherana camp will be on the left. Access to the mine is gained by a gravel track from the camp along Stag Creek. The main open cut is about 1 kilometer east of the old El Sherana mining camp and approximately 120 meters above the floor of the South Alligator River valley.

LOCAL GEOLOGY

The South Alligator River valley is dominated by a belt of tightly folded metasediments of the early Proterozoic era. The belt trends north-west for a length of about 60 kilometers with a width of approximately 10 km. The dominant strata in the region have been subjected to considerable erosion creating ridges as high as 300 metres. The tops of the ridges host felsic volcanics and sandstone from the early Proterozoic to Middle Proterozoic era. Most of the uranium deposits in the region occur within narrow basins of felsic volcanics and sandstone along a belt that trends north-west.

Laminated ferruginous shales host the primary ore-body at El Sherana, which occurs along a bedded fault contact with incompetent graphitic shales. The ore-body has a discontinuous tabular shape. In the vicinity of the ore-body the shales are severely fractured and dip in a south-easterly direction at about 70 degrees. Reddish brown cherty breccias are also associated with the ore body and the colour of the breccia is due to dust size particles of hematite. The breccia hosts irregular veinlets of quartz and chalcedonic silica. These veins often contain crystals of pyrite and small grains of Uraninite coated with meta-Torbernite.

For a detailed discussion of the Regional geology review the work of Friedmann in Stratigraphy, Sedimentology and Tectonic Evolution of the 1.86Ga El Sherana and Edith River Groups, Northern Territory, Australia by S. Julio Friedmann, Thesis, MIT, June 1990.

MINING HISTORY – A Brief Review

URANIUM PRODUCTION

Shortly after the initial discovery of the deposit in 1954, portable sleeping facilities for the workers were constructed on residential lease 2A beside Stag Creek. Further exploration of the El Sherana prospect then began in earnest. In 1956 a gravity separation plant was constructed about 2 kilometers SE of the main camp to process Uranium ore on site.

In 1956 UUNL signed a contract to supply 100 long tons of 50% Uraninite concentrate (U3O8) to the United States Combined Development Agency (CDA). Initial work focused on hand-screened Uraninite ore but after the construction of the gravity separation plant, the bulk of the contract was fulfilled with concentrates. The contract with the CDA was finalized in December 1957.

In April 1958 after two years of negotiations UUNL signed a contract with the United Kingdom Atomic Energy Commission (UKAEC) for the supply of 570 long tons of U3O8 at a rate of 100 long tons per annum.

In 1959, United Uranium N.L purchased the Northern Hercules Mill at the Moline mine, some 50 kilometers to the west of the El Sherana site and converted it to a solvent extraction Uranium plant. The processing of ore from El Sherana began at the Moline mill in May 1959.

From 1956 to the closure of the mine in 1964, El Sherana and El Sherana West collectively produced the greatest output of U3O8 of all the Uranium mines operating in the South Alligator Valley region.

PRODUCTION DATA

Some production figures (expressed as SI units) for the mine are given in the tables below.

PRODUCTION FIGURES

PROD U3O8

MINE (Ton) (kg/t) (kg)

El Sherana 1956-1959 39,054 5.20 202,935

El Sherana West 1961-1964 21,658 8.20 177,425

ORE IN SITU

DEPOSIT TON U3O8

(kg/t) (kg)

El Sherana 2,032 1.79 3,629

El Sherana West 8,596 6.18 53,149

GOLD PRODUCTION

From the very beginning of the mine the auriferous nature of the Uranium ore was well known. Ore residues from the gravity separation plant were trucked to the Rum Jungle plant for additional processing, and in 1957 the first Gold bar was cast. From then on Gold became an important by-product of mining at the El Sherana mine.

Once the UKAEC contract had been fulfilled Uranium mining at El Sherana was suspended. Unable to secure any additional Uranium oxide export contacts, UUNL decided to convert the mill at Moline to a Gold processing facility. Initial processing focused on tailings derived from the Uranium ore mined in the South Alligator valley Uranium field.

Between 1954 and 1964 approximately 143,000 long tons of Uranium ore were recovered from mines in the South Alligator Uranium field, with approximately 60,000 long tons being taken from the El Sherana leases. The El Sherana ore processed at Moline yielded 8,900 troy ounce of Gold, equivalent to approximately 5.45 grams of Gold to the metric ton of ore.

While the Moline mill was processing the tailings from previous Uranium mine work, the UUNL investigated the feasibility of converting the El Sherana mine into a major Gold producer.

UUNL commenced a preliminary drilling program to determine the extent of the Gold mineralization at El Sherana. UUNL had always felt that the Gold ore bodies at El Sherana were much more extensive than the Uranium ones, a fact that was confirmed by exploration work conducted by BHP in the late 1980’s.

Due to a reduced value in the price of Gold, approximately $35AUD per troy ounce at the time, the plan to relocate the Moline mill to El Sherana became an uneconomic venture and as a consequence all plans to mine Gold at El Sherana were suspended.

By the end of 1965 the Moline mill had finished processing all the Uranium residues from the mines in the South Alligator valley region. It was then used to process Silver, Lead and Zinc ore from the nearby Evelyn mine.

Exploration and assay work conducted by BHP in the late 1980’s indicated that the contained Gold in the El Sherana ore-body ranged from "trace" levels to 15g/t with sporadic high values of more than 30g/t. The work by BHP also indicated the presence of Platinum and some Palladium within the El Sherana leases.

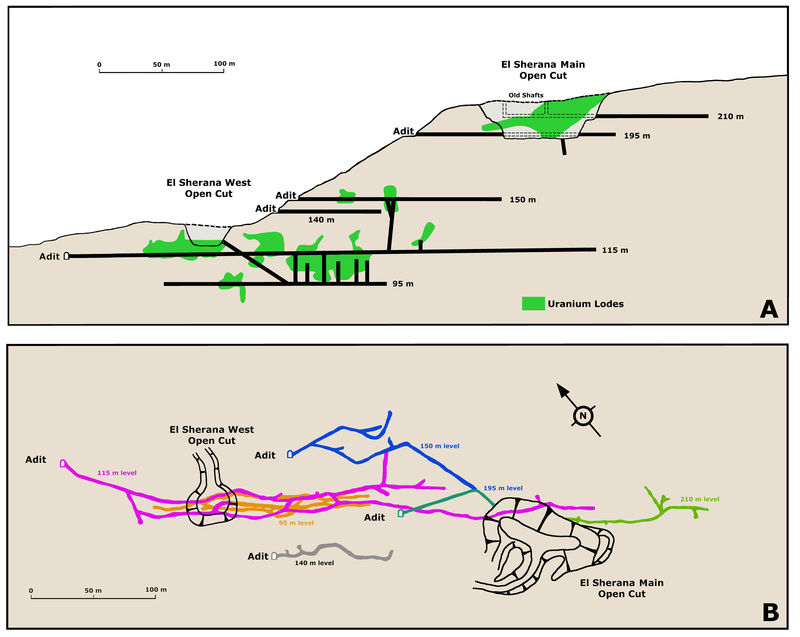

MINE LAYOUT

EL SHERANA

Initial exploration work focused on inclined diamond and vertical wagon exploration drilling followed by shaft sinking, adit driving and preliminary stoping.

Between 1956 and 1957 preliminary mining exploration discovered the existence of irregular lenses of very high grade Uraninite ore to a depth of 30 metres. The ore was enclosed in an extensive envelope of lower grade oxidised ore.

Two exploratory shallow shafts were sunk to access the rich ore. Initially high grade Uraninite ore was extracted from the 210 metre and 195 metre levels by selective cut and fill stoping. The Uraninite lenses present within the 210 metre level had a maximum width of about 17 metres while those uncovered in the 195 metre level had a maximum width of 30 metres. The size of the Uraninite ore body made open cut mining a viable option, and the old open cut is still visible in modern day aerial photographs.

EL SHERANA WEST

A significant radioactive anomaly over carbonaceous shales was discovered on the slopes of a small valley below the main El Sherana open cut in the late 1950’s. It was subsequently shown that this region also contained rich deposits of Uraninite. About 180 metres below the main El Sherana open cut another smaller open cut was developed and the west mine operated from 1961 to 1964.

The steep topography made the extraction of ore more amenable to underground mining techniques, and the rich ore was removed using cut and fill stoping which continued on the 95 metre level from an underlie shaft sunk on the base of the open cut. To access the additional high grade mineralized zones, adits were driven along the 115, 145 and 150 metre levels.

MINERALIZATION

URANINITE

The Uranium mineralization at the El Sherana leases was shown to occur over a 400 metre strike length with a vertical depth exceeding 180 metres and widths of up to about 30 metres. Uraninite frequently occurred as massive segregations, radiating columnar aggregates, veins and disseminations associated with minor amounts of Cobalt and Nickel Arsenides, Arsenopyrite, Pyrite, Marcasite, various Copper sulphate species, Galena and Clausthalite. The primary ore was often enclosed in an extensive envelope of lower grade oxidised ore. Bulbous isolated masses of Uraninite weighing more than 50 kilograms were very common at the El Sherana mine. It is a noteworthy fact that El Sherana yielded the largest single piece of Uraninite ever produced in the world. It weighed 850 kilograms (1,856 pounds).

Some specimens (>10 kg) of Uraninite recovered at the mine often contained networks of radial and concentric shrinkage cracks containing quartz, secondary Uranium minerals, selenides, sulphides and/or native Gold.

The colloform habit was the most common form exhibited by the Uraninite. Some collector quality specimens resembled ‘kidney ore’ and in some of the larger and better specimens seen at the mine, the radius of curvature of the individual lobes exceeded 15 cm.

Some of the Uraninite specimens recovered from the mine also contained voids containing crystals (ca. 1-2 mm) of Johannite. Other specimens of Uraninite were encased in halos of Gummite.

SECONDARY URANIUM MINERALS

The mine contained many secondary Uranium minerals resulting from the oxidation of the primary ore. Thus the main ore bodies contained extensive seams and masses of uranium ‘ochres’ containing complex mixtures of secondary uranium minerals – oxides, carbonates, sulphates, phosphates and silicates.

The list of identified secondary minerals included but was not limited to the following species: Autunite, Becquerelite, Dumontite, Johannite, Kasolite, meta-Autunite, meta-Torbernite, meta-Zeunerite, Renardite, Rutherfordine, Torbernite, Saleeite, Soddyite and Uranopilite. Of these only meta-Torbernite and Rutherfordine occurred in sufficient isolated quantities (hand-sized specimens) to be of interest to mineral collectors of the era.

Metatorbernite - Cu(UO2)2(PO4)2(H2O)8

Metatorbernite occurred as well-formed, apple green euhedral crystals to 10mm filling large cavities in matrix. Occasionally the meta-Torbernite occurred within veins intersecting the Uraninite.

At the El Sherana main open cut well defined Metatorbernite crystals, some to 10 mm in width, occurred along fracture faces within an assemblage (Koolpin stratum) composed of interbedded chert, ferruginous siltstone, carbonaceous shale and siltstone.

Rutherfordine, UO2CO3

Rutherfordine was the most abundant of the secondary Uranium minerals found at El Sherana. It occurred as fine-grained and earthy encrustations on the surface of the Uraninite. Occasionally voids within the Uraninite, some a few centimeters in diameter, were filled with bladed aggregates of long slender crystals of Rutherfordine. Veins of Rutherfordine, some several millimetres wide, occurred in shrinkage cracks and stress fractures within the Uraninite.

Massive and vuggy Uraninite from the El Sherana main open cut often contained veins and masses of Rutherfordine associated with meta-Torbernite. The chert, a common rock found in the main open cut, contained Rutherfordine as thin coatings in fractures and joint planes also associated with meta-Torbernite.

SOME NOTES ON MISLABLED EL SHERANA URANIUM MINERALS

Carnotite was not a mineral species observed at the El Sherana mines. Soddyite, Phosphuranylite and Vandendriesscheite were associated with Uraninite at the Pallette mine. Uranopilite did occur as a minor accessory mineral with some specimens of Uraninite from the El Sherana mine. Saleeite and Uranophane were seldom seen associated with any specimens of Uraninite from any of the mines within the South Alligator Uranium field.

| Description: |

Country Map Photo

The Northern Territory occupies the central position in the northern section of the Australian continent. Its coastline meets the Timor Sea, Arafura Sea, and the Gulf of Carpentaria to the north. To its west lies Western Australia, while South Australia forms its southern border. Queensland defines its eastern boundary. This diverse geography gives the Northern Territory ever changing landscapes, from tropical coastlines in the north to the arid desert regions in the south. The El Sherana mine is located in the South Alligator River valley region of the Northern Territory. The insert shows the geographical location of the Northern Territory in relation to the rest of the continent.

It is interesting to note that the term “Alligator” in reference to the Alligator Rivers’ Region of the Northern Territory and its three main rivers (East, South, and West Alligator), originated from a mistake made by Lieutenant Phillip Parker King. During his ground-breaking explorations between 1818 and 1822, he encountered numerous crocodiles in the estuaries of these rivers. In his journals, he noted the abundance of these large reptiles and mistook them for alligators, a species not indigenous to Australia. Thus he named the rivers "Alligator Rivers." Despite the scientific inaccuracy, the name stuck and is still used today to describe the region. |

|

| Viewed: |

2229 Time(s) |

|

| Description: |

Location Photo

Map of the location of the El Sherana mine within the South Alligator Uranium field. About 2 kilometres south of the main camp via Gimbat road is the location of the gravity Separation plant which was demolished sometime in the late 80’s or early 90’s. The location of the site of the plant is still clearly visible in recent (ca. 2023) aerial photographs.

The area contains numerous deposits of Uranium which were exploited from about 1953 to 1970. The first discovery of Uranium in the area occurred at Coronation Hill some 13 kilometers south–east of the El Sherana mine. The discovery was made in 1953 on Coronation day (June 2nd) by B. P. Walpole a Geologist working for the Bureau of Mineral Resources.

The most colourful deposit in the whole Uranium field was the Palette mine located about 7 kilometers south-east of El Sherana. It was reached by a winding, precipitous road whose access was often cut by the flooding of the South Alligator River during the wet season. It was at the same elevation as El Sherana. The Palette mine was a large fan shaped deposit adjoining a sheer white cliff face. Joe Fisher, mining consultant and pioneer of Uranium mining in South Alligator River, named the site ‘palette’ because he said the Uranium mineralisation reminded him of the colourful daubs of paint one might see on an artist’s palette. Eyewitness accounts spoke of a truly colourful place glittering magnificently in the sunlight where the hues of blackish Uraninite, orange Gummite, lime-green Autunite, apple-green Torbernite and dark-yellow Soddyite were clearly visible even from a distance of a hundred metres or more.

John Webb, who was the field Superintendant with the Australian Atomic Energy Commission’s at the time (1958) stated that many of the secondary Uranium minerals recovered at the Palette mine were superb collector pieces too good to be broken up and sold as ordinary Uranium ore. Regrettably few if any ‘collector quality’ specimens from this mine can be seen in modern day mineral collections.

Other mines in the area include but are not limited to Koolpin, Scinto, Cliff Face, Skull and Saddle Ridge. UUNL records indicate that El Sherana was the largest producer of Uranium ore in the region. |

|

| Viewed: |

2230 Time(s) |

|

| Description: |

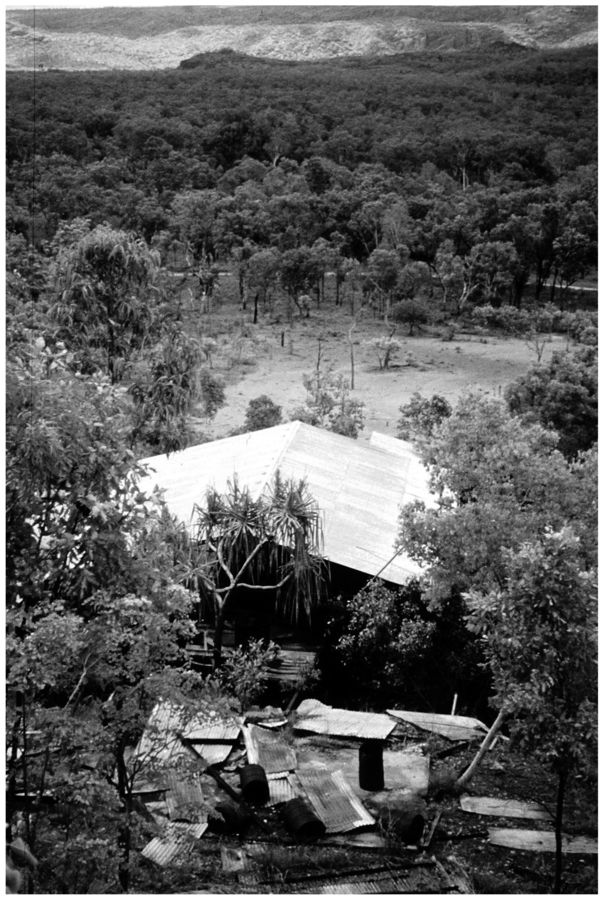

Aerial Photograph of the El Sherana Mine

Shown is an aerial photograph of the current status of the El Sherana mine. Visible is the camp containing a few derelict buildings. The main open cut is still intact but some areas of the open cut appear to be filled in by natural erosion of the surrounding terrain. Though the area was said to have been ‘rehabilitated’ sometime in the late 80’s or early 90’s the aerial photograph indicates that this was either not done or the work was sub-standard.

The El Sherana west open cut is still visible, but not as well-defined as seen in a photograph taken in 1963 by UUNL. The area is now overgrown with new and abundant vegetation, which I think, might have a fondness for Uranium. It is also likely that the area may have succumbed to subsidence or natural erosion of the benches. There are no records indicating that UUNL filled in the west open cut after the mine was put on care and maintenance in 1964. Photographs taken by BHP in the late 80’s show that the open cut was heavily overgrown with new flora native to the South Alligator River valley region. According to BHP staff (private communication) the open cuts provided many good homes for the abundant native fauna. Crocodiles you ask, most likely, but who knows?

The site of the Uranium Processing plant some 2 kilometres SE of the main camp (not shown in the above aerial photograph) was covered in soil in the late 80’s or early 90’s. The buildings on the site were demolished and the remains buried. This attempt to ‘rehabilitate’ can be seen in aerial photographs but it would appear that even here the mine is fighting back.

Height above sea level for some locations is given in metres.

Main open Cut Digital GPS location: -13.50932, 132.52067 |

|

| Viewed: |

2227 Time(s) |

|

| Description: |

Diagram of the Main Mine Working

Diagram A shows a longitudinal section of the mine in terms of the relative positions of all the main adits and open cuts. Diagram B shows the relative positions of the open cuts and the underground workings. The extension of the 195 metre level that lies SW of the main open cut is directly beneath the 210 metre level. All structures have been referenced to height above sea level. These diagrams are based on unpublished reports, UUNL maps, private communications and UUNL company note books. |

|

| Viewed: |

2228 Time(s) |

|

| Description: |

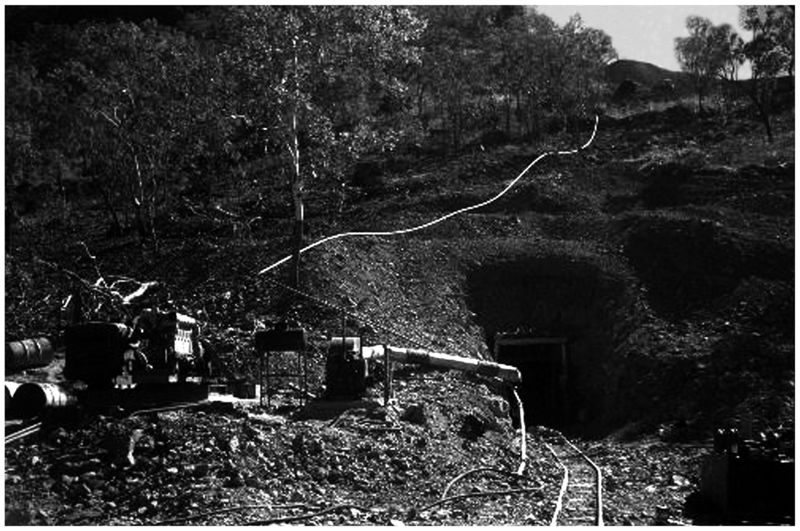

El Sherana Mine Photo showing Adit

An old adit set into a hill at El Sherana, note tracks leading into an adit (perhaps the 195 metre level) and the visible water pipes and machinery, El Sherana, NT late 1950’s. (Photo courtesy of R. Fisher) |

|

| Viewed: |

2223 Time(s) |

|

| Description: |

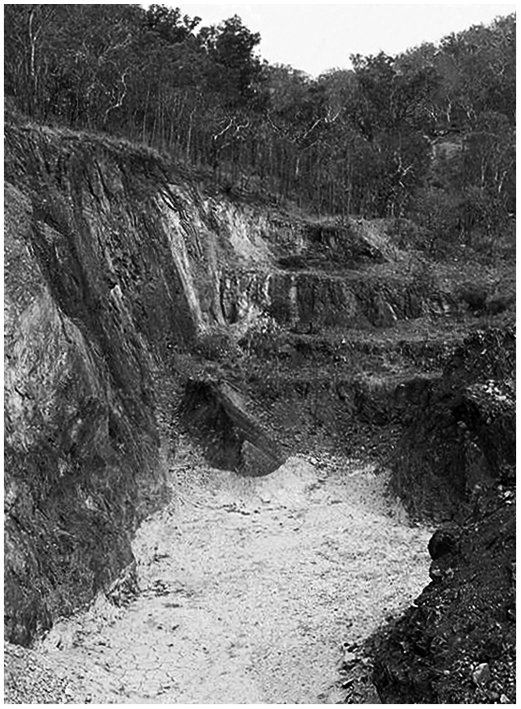

El Sherana West Photo

El Sherana West Open cut ca. 1963. The small open cut was set in some very steep terrain. Clearly visible in the background is the adit leading to the incline shaft which accessed the lower levels from which the bulk of the high grade Uraninite ore was extracted. In the foreground is a jeep bearing the logo of the United Uranium N.L. Company. (Photo courtesy of N. Murphy) |

|

| Viewed: |

2233 Time(s) |

|

| Description: |

El Sherana Photo

Part of the El Sherana open cut ca. 1988. (Photo courtesy of BHP) |

|

| Viewed: |

2223 Time(s) |

|

| Description: |

El Sherana Processing Plant

Photo showing part of the derelict remains of the El Sherana mine’s Gravity Separation Plant. The plant was constructed in 1956 to process the rich Uranium ore extracted from the nearby mines. Gimbat Road is in the background. (Photo courtesy of S. Kerber) |

|

| Viewed: |

2223 Time(s) |

|

| Description: |

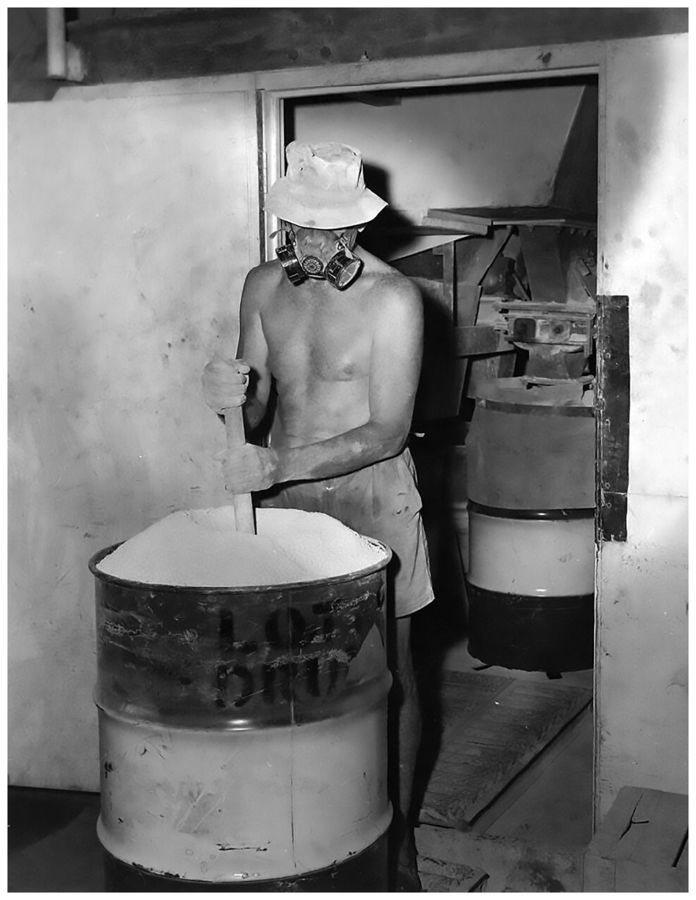

Processing El Sherana Uranium ore at moline

Shown is a photo of a worker ‘settling’ the Uranium ore concentrate into an appropriate steel container in a well-ventilated area. United Uranium N.L., Moline, Northern Territory, 1963. (Photo courtesy of J. Taylor)

The light colour of the product shown in the photo is indicative of Ammonium Uranyl Carbonate (AUC), commonly known as yellow-cake. An alternative compound supplied to the Nuclear Energy Industry is called AUD which is an abbreviation for Ammonium Diuranate, (NH4)2U2O7. AUD is much darker in colour than AUC with a greenish brown hue. For a detailed discussion on the solvent extraction of Uranium from Uranium ores see Ullmann's Encyclopedia of Industrial Chemistry, 40 Volume Set, 7th Edition, Section U, Uranium, Uranium Alloys, and Uranium Compounds; ISBN: 978-3-527-32943-4. |

|

| Viewed: |

2230 Time(s) |

|

| Description: |

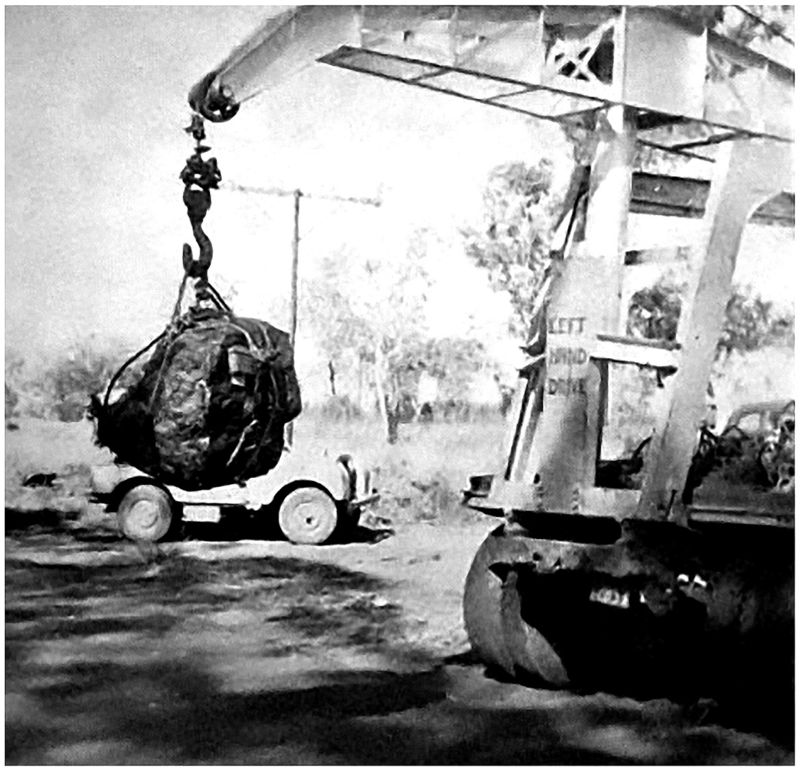

Uraninite being loaded

El Sherana yielded the largest single piece of Uraninite ever produced in the world. It weighed 850 kilograms (1,856 pounds). It was recovered at the El Sherana mine in May 1956. The specimen was purchased by the Australian Atomic Energy Commission for exhibition in Sydney. In the photo the specimen has been hoisted with the aid of a portable crane for loading into a suitable transport vehicle. (Original photo courtesy of F. Jones) |

|

| Viewed: |

2225 Time(s) |

|

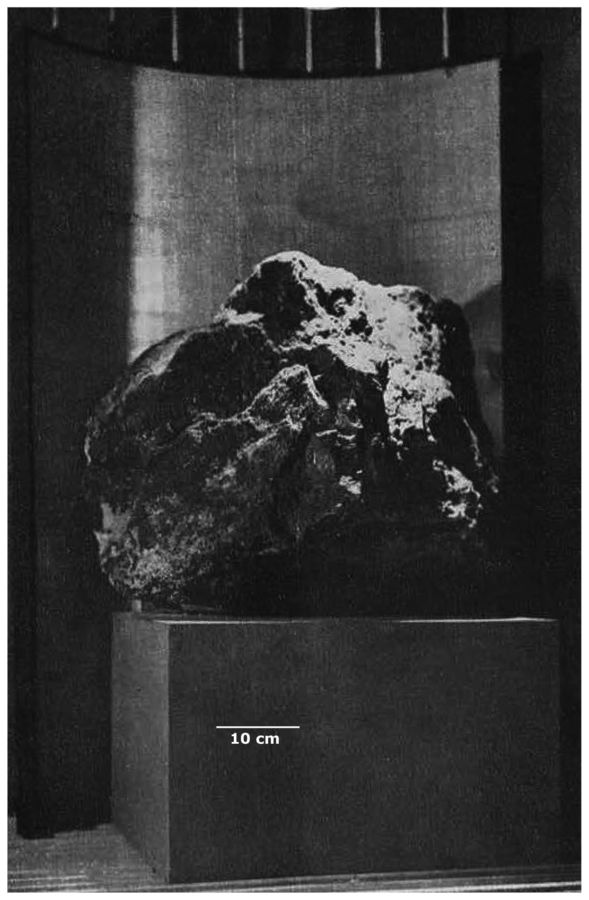

| Description: |

El Sherana Uraninite at the Australian Museum

Between 1961 and 1983 the Sydney based ‘Australian Museum’ proudly exhibited a huge specimen of El Sherana Uraninite. At the time it was the largest specimen of Uraninite ever recovered, and weighed approximately 850 kilograms. It measured 48 cm high and 46 cm wide. The specimen was recovered at El Sherana in May 1956. The potential radiation threat from this superbly wonderful and scientifically priceless specimen was thoroughly assessed by Health and Safety experts from the New South Wales Health Department. These experts stated and I quote “after measuring the amount of radiation from this big specimen, to obtain the maximum permissible dosage a member of the public would have to stand on the spot from where the specimen can be viewed for half an hour every day for the rest of his life. Therefore, the amount of radiation received by any member of the public from casual viewing is quite negligible.” – End of quote. As an additional precaution an exhaust fan was installed in the outside wall behind the specimen to remove the small amount of Radon emitted from the outer most surface (ca. 1-2 mm) of the specimen.

Sometime in the early 1980’s The Australian Museum gave the specimen to ANSTO for safe keeping at their Lucas Heights facility. According to ANSTO and its regulatory partner ARPANSA, the current location of the specimen is unknown.

Another similar, but smaller, specimen of Uraninite from El Sherana was displayed in the British Museum in London, but its current whereabouts is also unknown.

El Sherana Uraninite was dated at about 1800 Ma.

Before the El Sherana specimen was recovered, the previous weight record for a single specimen of Uraninite was held by the Shinkolobwe Mine in the Katanga Province of the Democratic Republic of the Congo. The Shinkolobwe specimen weighed 750 kilograms. (Original Photo courtesy of R. Chalmers) |

|

| Viewed: |

2239 Time(s) |

|

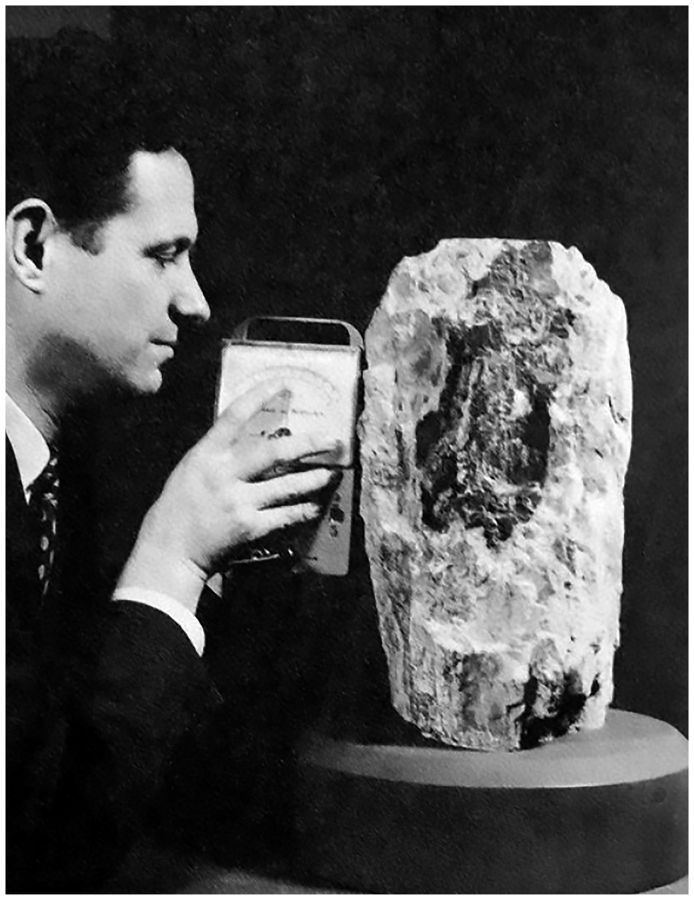

| Description: |

Uraninite at the AMNH – The American Connection

Included for comparison is a photograph of what might be the third largest Uraninite specimen to be publically exhibited in recorded history. The specimen weighed just over 60 kilograms and consisted of an inner core of Uraninite covered in a ‘deliciously’ thick layer of Schoepite. It was exhibited for many years at the American Museum of Natural History (AMNH). In the photograph Dr. Brian H. Mason (1917-2009) Curator of the Department of Physical Geology and Mineralogy at the Museum (1953-1965) can be seen measuring the radiation from the superb specimen. The specimen was donated to the AMNH in 1955 by Vernon J. Pick and it came from the Pick's Delta Mine, San Rafael Swell Mining District, Emery County, Utah, USA. What a fine specimen to have in a private collection – the mineralogical stories it could tell and the secrets it could reveal – truly amazing and absolutely beautiful!

I think some folks might find the following piece of historical trivia interesting. Dr. Mason was an expert on meteorites and was the first scientist to suggest that some meteorites found in Antarctica were in fact moon rocks. Between 1962 and 1965 Dr. Mason took part in several Australian-American expeditions to the clay pans in central South Australia in search of Australites (Tektites). The Australian team was led by R.O Chalmers, Curator of Minerals at the Australian Museum and the man largely responsibility for the acquisition of the fantastic specimen of Uraninite from El Sherana. Dr. Mason also had two minerals named in his honour, Brianite a Sodium-Calcium-Magnesium phosphate mineral (Na2CaMg(PO4)2) and Stenhuggarite a rare Calcium-Iron-Antimony mineral (CaFeAs2SbO7). The mineral name Stenhuggarite is a clever use of the Swedish word Stenhuggare for stonemason honouring Dr. Mason’s work as the proverbial stone man. Asteroid 12926 Brianmason is also named in his honor. In 1965 he became Curator of Meteorites in the Department of Mineral Sciences at the Smithsonian Institution in Washington, retiring in 1984. (Photo courtesy of B. Kramer). |

|

| Viewed: |

2238 Time(s) |

|

| Description: |

Uranium Specimens in storage at the AMNH

On the right is a 60 kg specimen of Uraninite with Schoepite from Pick's Delta Mine, San Rafael Swell Mining District, Emery County, Utah, USA. It is the same specimen shown in the earlier picture which featured Dr. Brian H. Mason. Just look again at that deliciously thick layer of Schoepite with some Uraninite just visible in the lower right hand corner – superb!

On the left is a 15 kg specimen of Uraninite with Schoepite from the Lookout No. 22 claim, Marshall Pass, Saguache County, Colorado, USA. Both specimens are now in storage at the AMNH (Photo courtesy of AMNH) |

|

| Viewed: |

2239 Time(s) |

|

|

|

silvia

Joined: 10 Oct 2021

Posts: 264

Location: UK

|

Posted: Jul 22, 2025 15:04 Post subject: Honoring Mexican Magic Posted: Jul 22, 2025 15:04 Post subject: Honoring Mexican Magic |

|

|

MILPILLAS

The Rich Tapestry of Mineral Collecting

‘An extract from my fully illustrated free eBook’

INTRODUCTION

For many, the world of mineral collecting conjures images of glittering geodes, perfectly formed crystals, and vibrant hues displayed under museum lights or in private cabinets. It is, undeniably, a pursuit of beauty, a quest for the rare and the visually arresting. Yet, to truly appreciate a mineral specimen — to understand its profound significance and the silent narrative it carries — one must look beyond its superficial allure. What follows is an invitation to take a journey that transcends mere aesthetics, delving into the intricate layers of science, industry, and human history that imbue each mineral with a story far richer than its outward appearance suggests. Our backdrop for this exploration will be the famed Milpillas Mine in Sonora, Mexico, a locality that has yielded some of the world's most exquisite Copper minerals, offering a perfect lens through which to view my multifaceted passion.

MILPILLAS MINE

The Milpillas Mine, nestled in the arid landscapes of Sonora, is renowned for its spectacular Azurite and Malachite specimens. These Copper carbonates, with their deep azure blues and verdant greens, are visual masterpieces, often forming breathtaking sharp, lustrous crystals. A mineral collector might be captivated by the sheer vibrancy of a Milpillas Azurite, its color so intense it seems to absorb light or the chatoyant allure of Malachite giving it the appearance of the finest velvet. This initial visual appeal is undeniably powerful, drawing us into the mineral kingdom. However, to stop there is to miss the profound scientific and social drama encapsulated within each piece.

SCIENCE

Consider the very existence of Azurite and Malachite. These minerals are not merely pretty rocks; they are tangible records of complex chemical and physical processes. Their formation at Milpillas is a testament to supergene enrichment, a geological phenomenon where primary Copper sulfides, deep within the earth, are oxidized by circulating groundwater. This process liberates Copper ions, which then react with carbonate-rich solutions to precipitate these vibrant richly coloured minerals. The subtle differences in water availability, carbon dioxide concentration, and pH determine whether Azurite or Malachite forms, often in close association. Each crystal's habit — its specific shape, colour and growth pattern — is a direct consequence of the physics governing its atomic lattice and the environmental conditions during its crystallization. The study of these minerals, even for a novice collector, therefore, becomes an engaging lesson in geochemistry, crystallography, quantum mechanics and the dynamic forces that shape our planet. An astute mineral collector understands that a mineral’s beauty is not just in the color, but in the elegant chemical reactions and precise atomic arrangements that give rise to that color.

MINING

Furthermore, a comprehensive understanding and appreciation of fine mineral specimens necessitates a deep dive into the human endeavor that brings them to light - mining. The mineral specimens from Milpillas, whether painstakingly extracted from an isolated pocket by a dedicated miner or taken randomly off an ore dump, are products of specific mining methods. Was the mine an open-pit operation, or was it an intricate network of underground tunnels? What drilling, blasting, and excavation techniques were employed? How did these methods influence the preservation or damage of delicate crystal pockets? Knowledge of these processes allows the mineral collector to appreciate the journey of the specimen from its deep geological resting place to the light of day.

METALLURGY

Beyond extraction, there is the crucial field of extractive metallurgy. Milpillas was primarily a Copper mine, meaning the vast majority of the material extracted was destined for processing to yield pure Copper metal. Understanding the flotation, leaching, and purification processes used to separate Copper from its ore provides context for why certain minerals are considered “ore minerals” and others “gangue.” It highlights the economic drivers behind the mine's existence and the sheer scale of human ingenuity required to transform raw earth into essential resources. This industrial backdrop is an integral part of a mineral's story, connecting it to global supply chains and technological advancements.

CULTURE

Perhaps most poignantly, a mineral specimen from Milpillas is a tangible link to the culture and history of the society in which the mine operated. Mining in Mexico has a rich and ancient heritage, deeply interwoven with the nation's pride, identity and economy. The Milpillas Mine, like many others, was not just a geological site; it was a community, a workplace, and a source of livelihood for countless individuals. Each specimen, therefore, carries echoes of the miners who toiled underground, the engineers who designed the operations, and the families whose lives were shaped by the mine's rhythms. It speaks of economic booms and busts, of labor relations, environmental considerations, and the evolving relationship between humanity and the earth's resources. To collect a mineral from Milpillas is to hold a piece of Mexican history, a fragment of its industrial development, and a silent testament to the resilience and spirit of its wonderful people.

COMMUNITY

Beyond the initial thrill of acquiring a fine Milpillas Azurite or even a rare Volborthite, the true wealth of mineral collecting lies in the human connections it fosters. This isn't merely a solitary pursuit of geological treasures; it's a vibrant community where shared passion for Earth's artistry binds strangers into lifelong friends. From seasoned experts generously imparting decades of wisdom to fellow enthusiasts swapping tales of epic digs, the journey into mineralogy is illuminated by the people you meet — mentors, collaborators, and companions who enrich every facet of this captivating hobby. Prepare to discover not just exquisite specimens, but an invaluable network of kindred spirits.

PROMISE

In essence, mineral collecting, when approached with curiosity and a desire for a deeper understanding, transforms into a rich mosaic — a multidisciplinary exploration that weaves together the threads of chemistry, physics, geology, engineering, economics and human culture. It is a pursuit that challenges the mind as much as it delights the eye, offering profound insights into the natural world and our place within it.

My aim is to illuminate these connections, encouraging you to see beyond the superficial sparkle and discover the extraordinary narratives held within every mineral specimen. Hopefully this will make your collection of minerals not just a display of beauty, but a library of Earth's remarkable stories.

So let the story of the Milpillas mine begin and welcome to Silvia’s collection. Aproveite!

“No part of the text, diagrams or photographs contained herein may be reproduced, distributed, or transmitted in any form or by any means, without the prior written permission of the copyright holder. Reproduction for commercial purposes is strictly prohibited.”

| Description: |

|

| Viewed: |

530 Time(s) |

|

| Description: |

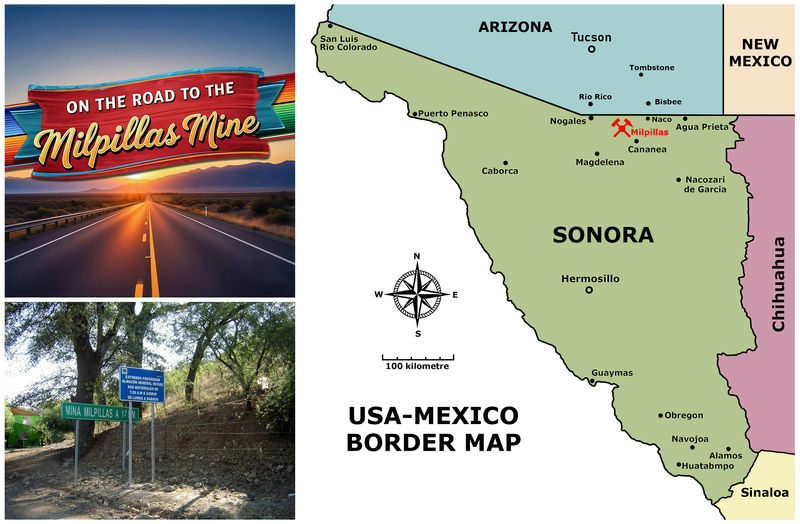

ON THE ROAD TO THE MILPILLAS MINE

LOCATION

The Milpillas Copper Mine, also known as La Parreña Mine, is located in the Santa Cruz Municipality of Sonora. Sonora is a large state located in northwestern Mexico. It borders the U.S. states of Arizona and New Mexico to the north, the Mexican states of Baja California to the west, Chihuahua to the east, and Sinaloa to the south. Its western edge lies along the Gulf of California (Sea of Cortez). Much of the state is covered by the Sonoran Desert.

The Milpillas Copper Mine is located approximately 40 kilometers (25 miles) south of the US-Mexico border, positioning it as an integral part of a larger, cross-border mining region deeply connected to Arizona's long-standing mining industry. Specifically, it lies about 60 kilometers (37 miles) southwest of Bisbee, Arizona, a town renowned for its Copper mining history. Tucson, a significant city in Southern Arizona, is roughly 188 kilometers (117 miles) to the north-northwest.

Closer to home, the Milpillas mine is situated about 20 kilometers northwest of Cananea, a significant Mexican mining center with a population of 30,000. Cananea's economy heavily relies on the large Buena Vista del Cobre mine. The closest settlement to the Milpillas Mine (La Parreña) is the small village of Milpillas, with just over 170 residents. Other nearby communities, such as Cuitaca and Vicente Guerrero, underscore the area's rural and mining-focused character. Access to the Milpillas site from Cananea involves navigating a mix of paved, secondary, and unpaved mining roads.

BRIEF HISTORY

The Milpillas Mine in Sonora, Mexico, discovered in 1978, faced an uphill battle for development. For decades, it lay dormant, hampered by low Copper prices and significant geological hurdles, most notably being buried beneath 250 meters of water-saturated alluvium. However, extensive exploration efforts by Minera Cuicuilco and Industrias Peñoles between the 1980s and 2001 ultimately confirmed substantial high-grade Copper reserves.

Underground mining operations for Copper finally began in 2006. Milpillas quickly gained fame not just for its Copper, but also for its world-class mineral specimens, particularly the striking "electric blue" Azurite crystals, Malachite, and Cuprite found in its supergene enrichment zones. Despite its geological riches, operations were indefinitely suspended in 2020 due to high costs and falling Copper prices. Fortunately, mining activities resumed in June 2022 and are ongoing.

Geological Setting and Mineralization

The Milpillas mine is discreetly situated within the Cuitaca Graben, a prominent north-south trending extensional basin within Sonora's Basin and Range province. The valuable Copper deposit was initially concealed beneath younger layers of Tertiary gravels and Quaternary alluvium. The underlying geology primarily consists of volcaniclastic rocks from the Laramide Mesa Formation and older Jurassic Henrietta Formation, which have been intruded by monzonitic to quartz monzonitic porphyry stocks. High-grade supergene enrichment, a process that generated the mine's renowned Azurite, Malachite, and other secondary Copper minerals, occurred within these host rocks at depths ranging from 150 to 750 meters below the surface.

Climate, Flora, and Fauna

Milpillas experiences Sonora's characteristic arid to semi-arid climate, set within a Basin and Range topography of alternating mountain ranges and expansive valleys. While higher elevations near Cananea support scattered pine-oak forests, Milpillas' immediate vicinity is a typical desert environment at lower elevations. The flora is well-adapted to drought, including various cacti (such as nopal and barrel cactus), mesquite trees, creosote bush, and resilient desert grasses and shrubs. The fauna, equally suited to these conditions, includes coyotes, diverse rodents, and numerous reptile species, such as snakes and lizards. |

|

| Viewed: |

527 Time(s) |

|

| Description: |

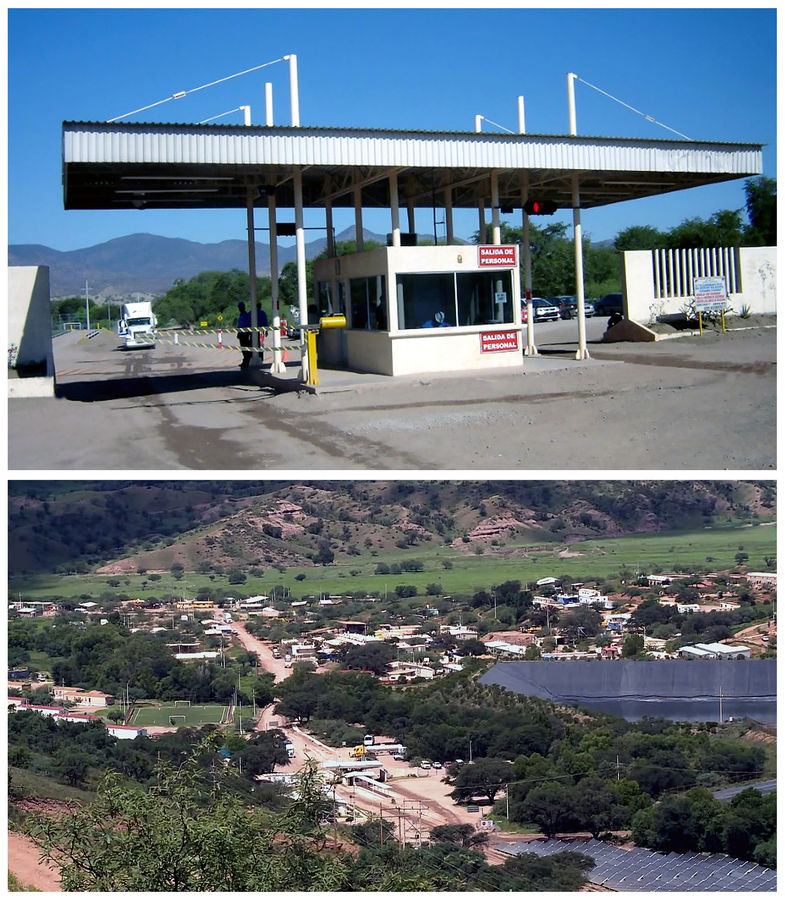

ENTRANCE TO THE MILPILLAS MINE

In the close-up photograph (ca. 2008), the entrance to the Milpillas Mine is clearly visible, a testament to its prominent presence. Even from approximately one kilometer away, as seen in the more distant image (ca. 2017), the mine's entrance remains discernible. Looking at the lower photo, the impressive solar thermal plant at Milpillas comes into clear view. This facility, notably one of Mexico’s largest solar thermal plants, was constructed in 2016. It boasts a substantial collector area of 6,270 square metres and delivers an impressive output of 8,600 MWh/year. This innovative installation has played a crucial role in significantly reducing the mine's reliance on diesel for its Copper electro-winning process.

The mine’s operational history was marked by a transition from easily accessible, high-grade oxide ores to deeper sulphide deposits. This shift, influenced by fluctuating Copper prices and geological realities, led to a temporary closure and subsequent reopening. This illustrates the inherent volatility and adaptive nature of the mining industry. Environmentally, the mine, like all extractive operations, faced challenges related to water use in an arid region and waste management. Socially, it contributed to local employment while navigating the broader complexities of large-scale industry within small local communities. Ultimately, Milpillas served as a reminder that mining, even when geologically exceptional, is a complex endeavor balancing economic gain with environmental responsibility and social considerations.

Copper mineralization at Milpillas was primarily hosted within altered intrusive rocks and, to a lesser extent, surrounding host rocks. The process began with the emplacement of a large, hydrous, and metal-rich magma at shallow to moderate crustal depths. As this magma cooled and crystallized, residual volatile phases, including water, sulfur, and metals like Copper, become progressively concentrated in the remaining melt. When the pressure of these exsolving fluids exceeded the lithostatic pressure, they were released, often explosively, through fractures and faults, forming a pervasive network of veins and disseminations.

These hot, acidic, and metal-laden hydrothermal fluids interacted with the surrounding rocks, leading to extensive hydrothermal alteration, such as potassic, phyllic, and argillic zones. As the fluids migrated and cooled, changes in temperature, pressure and pH, along with mixing with meteoric waters, caused the precipitation of Copper-bearing minerals.

Chalcocite underwent additional oxidation within the upper supergene zone. This process, driven by oxygenated waters, led to the dissolution of Chalcocite and the subsequent precipitation of various secondary Copper minerals. Notably, vibrant blue Azurite and green Malachite formed, often as stunning crystal specimens. Frequently, pseudomorphs were observed, where Malachite replaced Azurite while retaining its original crystal habit. Other secondary minerals, such as Cuprite and Brochantite, were also formed, reflecting the complex chemical transformations that occurred in this rich Copper deposit.

Original photos courtesy of Jaime Suberville |

|

| Viewed: |

527 Time(s) |

|

| Description: |

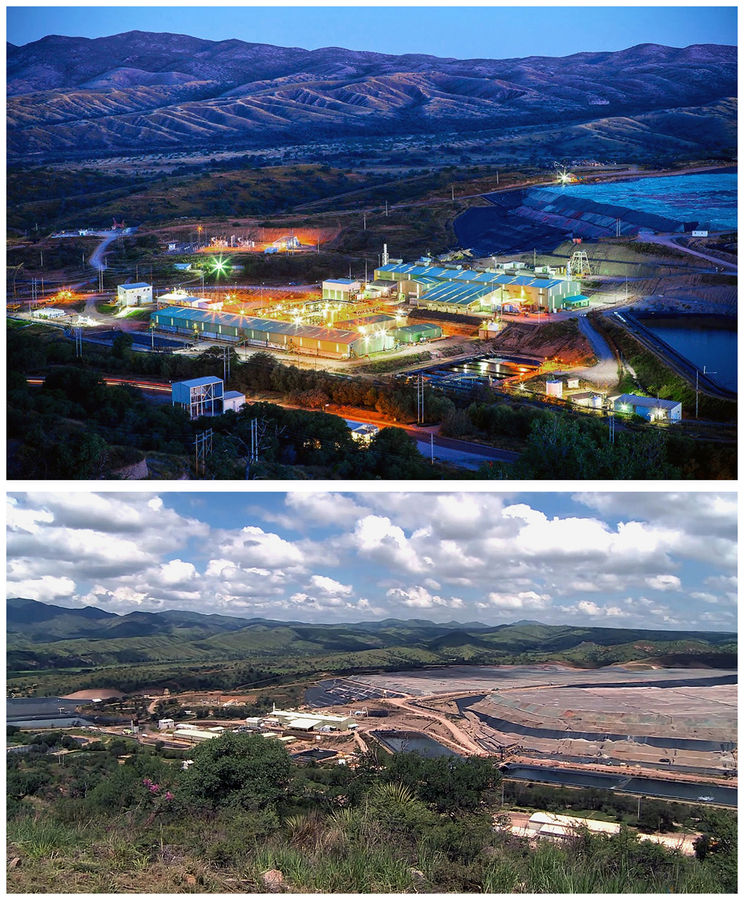

MILPILLAS MINE BY NIGHT AND BY DAY

These photographs capture groundbreaking moments at the Milpillas Solvent-Extraction and ElectroWinning plant, presenting both night and day perspectives. Prominently featured in the upper right section of the images are the crushed Copper ore leach pads and the associated ponds, which are notably rich in acid-leached Copper solution. The building at the top, the one closest to the heap leach pads is the electrowinning plant.

Commissioned in 2005, this advanced facility was the outcome of a significant partnership between Outokumpu Technology, a leader in metallurgical solutions, and Industrias Peñoles. Outokumpu's extensive involvement ensured the plant, initially designed for 45,000 tons of high-purity Copper cathodes annually (with an expansion to 65,000 tons by 2008), would be a success for Compañía Minera La Parreña. Like its counterpart in Laos, Milpillas didn't just become part of Mexican mining history; it also perfectly illustrated the significant technological shifts in Copper production at the turn of the millennium.

Unlike many mines that produce Copper concentrate, Milpillas produced high-purity Copper cathodes through a sophisticated process of underground mining, heap leaching, solvent extraction (SX), and electrowinning (EW). This integrated approach bypassed the need for smelting and refining elsewhere, streamlining the journey of Copper from its ore state to a commercially valuable product.

Original photos courtesy of Alanís Ortega |

|

| Viewed: |

527 Time(s) |

|

| Description: |

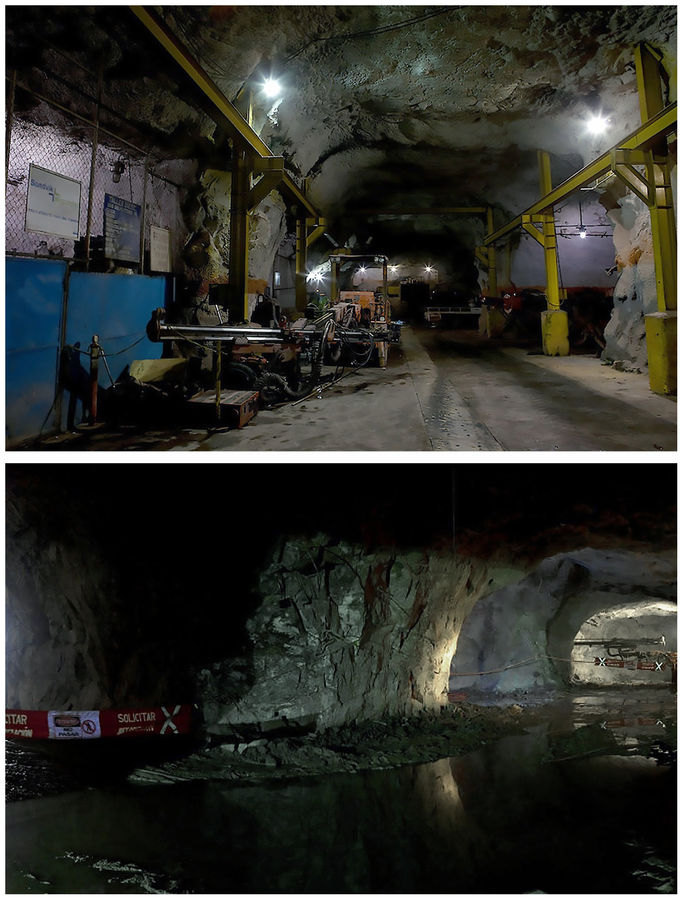

MILPILLAS UNDERGROUND - STORAGE ZONE

The nature of the Milpillas mine’s underground drives and storage areas was intrinsically linked to its “cut-and-fill” mining method and the unique geological characteristics of the deposit. The mine's infrastructure consisted of a network of drives (tunnels) excavated to access and extract the ore. These drives were carefully designed to follow the complex ore bodies, which included lenticular, flat-lying oxide zones at varying elevations, as well as deeper supergene sulphide zones. The underground layout facilitated the movement of equipment, personnel, and ore, as well as providing ventilation and drainage. To maintain ground stability in the created voids, waste material or cemented fill was introduced, creating a new working platform for the next mining cycle. This systematic approach allowed for selective extraction, maximizing recovery of the valuable Copper while ensuring operational safety and efficiency.

Storage areas underground are typically integrated into the mining cycle. After extraction, ore was crushed within the mine and then transported to surface leaching yards. Given the “cut-and-fill” method, excavated areas were often backfilled with waste material after ore removal, contributing to ground stability. While specific storage capacities for raw ore underground are not widely detailed, the efficient flow of material from extraction to surface processing implied a well-managed system for temporary holding and transport within the mine's extensive network of tunnels. A significant challenge for underground operations at Milpillas was water management, as the mine historically faced issues with flooding due to groundwater infiltration. Efficient pumping systems were crucial to dewater the mine and ensure safe and continuous operations. Once the ore was extracted, it is brought to the surface for further processing.

Original photos courtesy of Max Lomelín |

|

| Viewed: |

533 Time(s) |

|

| Description: |

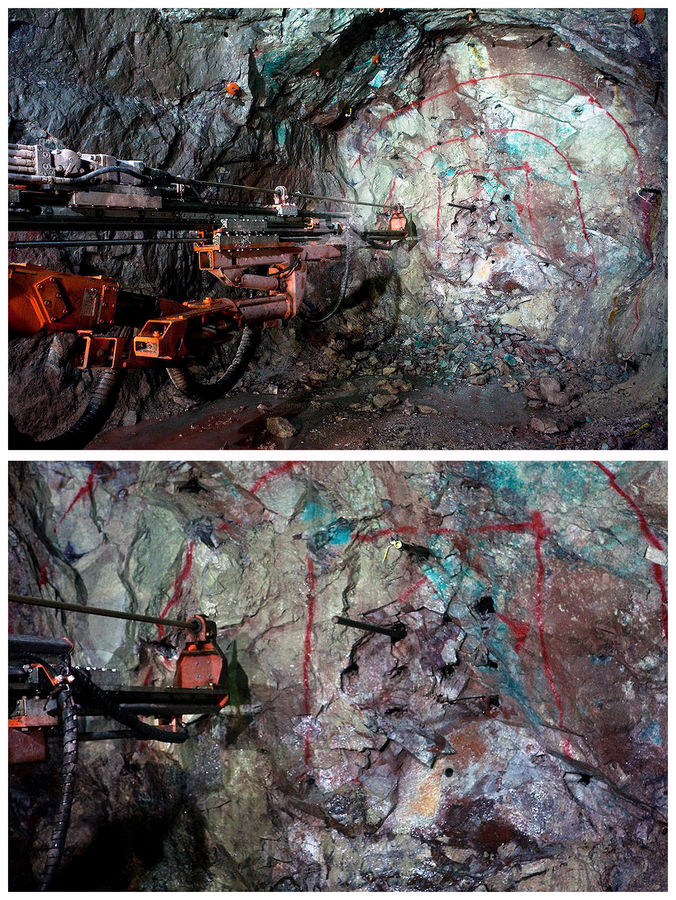

DRILLING UNDERGROUND

In underground mines like Milpillas, specialized long-hole drill equipment was paramount for preparing rock for blasting. These powerful drills created deep, precise boreholes into which explosives were loaded. This allowed for controlled detonation, breaking up the ore body into manageable sizes for extraction, a crucial step in the mine's production cycle.

On a daily basis, miners navigated a subterranean world where the primary target was high-grade Chalcocite, a crucial Copper sulfide ore found within the mine's extensive enriched blankets. However, earlier operations, before the sulphide zone was reached, brought them face-to-face with a stunning array of secondary Copper minerals, particularly prevalent in the shallower, oxidized zones of the deposit. These encounters routinely included the visually striking blue Azurite and its verdant counterpart, Malachite, which often display intricate intergrowths or even pseudomorphic transformations. Furthermore, the miners commonly observed the lustrous red Cuprite and deposits of glimmering native Copper. While less frequent, other notable green Copper minerals such as Brochantite and the distinctive blue-green Chrysocolla might also be present, alongside occasional rare silicates, painting a vivid picture of the mine's diverse mineral composition. The mine was well-known for producing exceptionally well-crystallized Volborthite, a rare Copper poly-vanadate, sometimes found on a matrix of Dickite or associated with Azurite and Malachite.

The photographs also highlight the relative scarcity of significant ‘collector-quality’ mineralized pockets conducive to specimen collecting. The Milpillas Mine, despite its economic prowess as a Copper producer, wasn't uniformly “mineralogically rich” in the way some mineral collectors often dream. While extensive zones yielded abundant Copper ore, the frequent discovery of collector-quality Azurite and Malachite vugs, brimming with “splendent” crystals, was not an everyday occurrence. Like many commercial mining operations, Milpillas had its hot spots; certain areas provided significant quantities of high-grade Copper ore for the electrolytic plant, while others, some distinct from the primary ore body, provided treasure troves for exceptional mineral specimens. This dichotomy is a common reality in the world of mineral collecting, where the pursuit of stunning crystals often means sifting through vast amounts of economically viable yet aesthetically uninteresting ore.

When routine mining operations intersected mineralized veins and vugs, some large, containing exceptional Azurite and Malachite crystals, these occurrences were opportunistically exploited by ‘some workers’ as a means of illicit income supplementation. Penoles, the owners and operators of the mine, actively discouraged such unauthorized extraction, enforcing a strict policy of dismissal and potential criminal prosecution for apprehended individuals. Furthermore, any worker implicated in such illicit activities faced industry-wide blacklisting, effectively precluding future employment within the mining sector.

Initially, the value of these surreptitiously acquired specimens was nominal, commanding only a few pesos. However, the Internet facilitated a rapid increase in market awareness among the miners, who quickly discerned the substantial value placed on these “colored rocks” by International, particularly North American, dealers and collectors.

A NOTE ON “THIS-OR-THAT POCKET” NOMENCLATURE

The use of the term “pocket” to describe certain Milpillas mineral specimens, particularly in reference to their extraction point, transcends simple geographical identification. These labels, rather than being intrinsic descriptors understood by those who extracted the specimens, were often marketing tools designed to imbue the minerals with a specific allure. Those intimately familiar with the mine's day-to-day operations understood that such terms were colloquialisms, not reflections of actual geological structures or mining methodology.

While official company documents certainly highlighted and celebrated areas with significant mineralization — often featuring stunning, perfectly formed crystals of Azurite, Malachite, and other Copper minerals — they deliberately avoided calling these spots “pockets.” Instead, they used more formal geological terms. Their descriptions focused on the geological structures controlling the mineralization, the types of rocks surrounding the minerals, and their exact mineral makeup. This intentional choice of language pointed to a clear difference between the casual, on-the-ground language used by some of the mine workers who opportunistically and illegally exploited the mineralized zones for personal profit and the precise, scientific terminology preferred in corporate and geological reports. It was likely an effort to keep all official communications consistent and scientifically accurate, ensuring a formal narrative throughout.

Original photos courtesy of Gonzáléz Sánchez |

|

| Viewed: |

526 Time(s) |

|

| Description: |

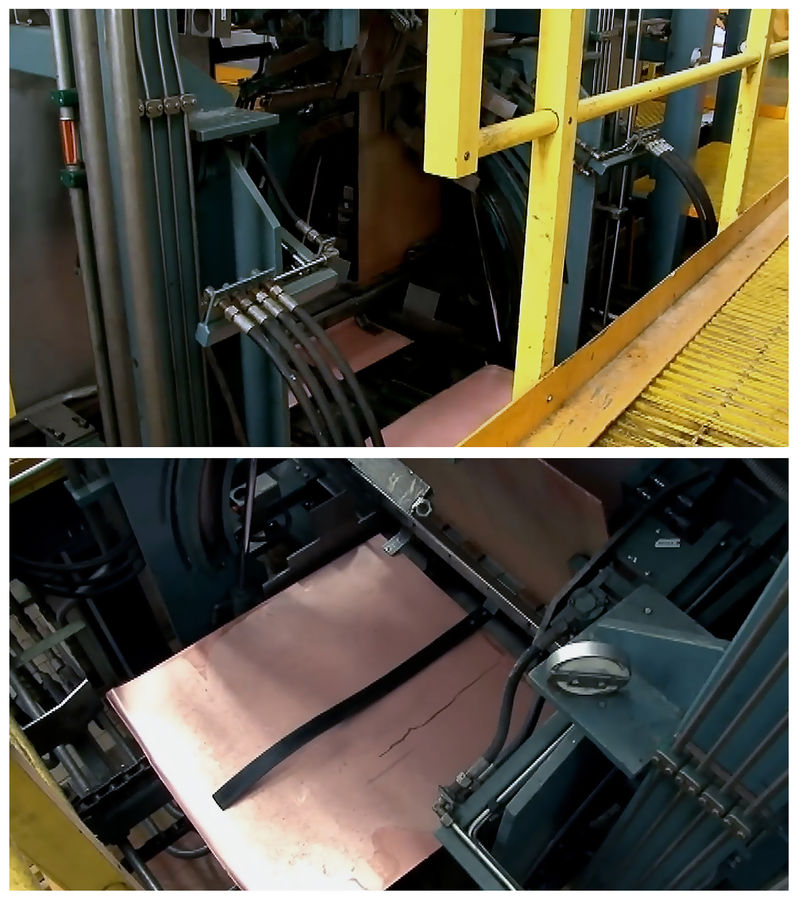

MUCKING, LOADING AND CRUSHING OF BLASTED ORE

The mining process at Milpillas began with the cut-and-fill mining method, ideal for steeply dipping ore bodies. After drilling and blasting, fragmented Copper ore within the underground stopes was scooped up using Load-Haul-Dump (LHD) vehicles, as seen in Photo A. These vehicles efficiently scooped up the broken ore, or “muck,” from the stope floor.

These highly maneuverable LHDs transported the muck over short distances to designated ore passes. These vertical or inclined shafts utilized gravity to move the ore to lower levels of the mine. From there, the muck was transferred to underground crushers for initial size reduction, as seen in Photo B.

Crushing was a fundamental initial processing stage. Large run-of-mine ore, some exceeding a meter in size, first underwent primary crushing in powerful gyratory crushers (Photo C), reducing the ore to a manageable size, typically a few centimeters. Subsequently, secondary and sometimes tertiary crushing stages further decreased the particle size. This meticulous size reduction was crucial for liberating valuable Copper minerals from waste rock and preparing the ore for subsequent grinding and leaching processes, maximizing extraction efficiency.

At Milpillas, the mine utilized a Metso Superior MKIII gyratory crusher (Photo C) as its primary crushing unit. During its lifetime, the crusher underwent several optimization phases to increase the lifespan of wear-prone components, dramatically reducing maintenance downtime from six months to two years. This enhancement led to lower production costs and improved personnel safety. It is interesting to note that the “ball” of the “gyrator” as seen in Photo C was nearly 1.5 meters in diameter, so the whole crusher unit was huge!

After crushing, the ore was transferred onto conveyor belts (Photo D), which transported it to the surface via a hoist shaft, where it then entered the leaching process.

As each horizontal slice of ore was mucked out, the void created was immediately backfilled with a cemented waste material. This backfilling provided vital ground support and created a stable working platform for the subsequent mining cycle of the next slice above, thereby ensuring a continuous and safe mining environment.

Original photos courtesy of Enrique Jimenez |

|

| Viewed: |

527 Time(s) |

|

| Description: |

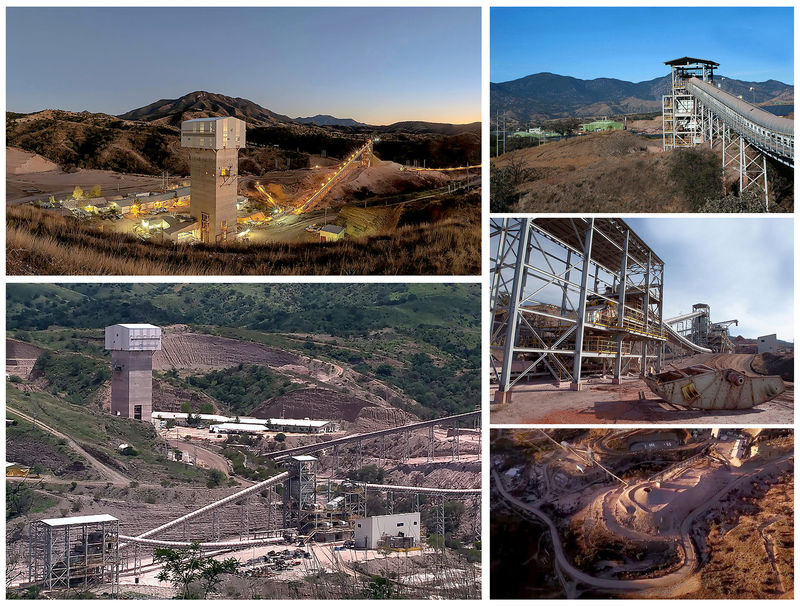

HAULAGE SHAFT NIGHT AND DAY WITH CONVEYOR SYSTEM

The Mine, utilized a main haulage shaft as a critical artery for material transport. After the Copper ore was extracted from stopes and crushed underground, it was transferred to the surface via a series of underground conveyor systems. Haulage shafts remain a critical component in modern underground mining, especially as operations extend to greater depths. While declines and ramps are suitable for shallower deposits, vertical shafts become more economical and often necessary for efficient transportation of ore, personnel, equipment, and for vital functions like ventilation and utility corridors.

Contemporary mines leverage advanced technology in haulage shaft design and operation. Modern hoists, often powered by variable frequency controlled AC drives, facilitate rapid and high-capacity movement of skips (for ore) and cages (for personnel and materials). Automated skip loading systems and real-time monitoring of shaft conditions, often through LiDAR-based 3D scanning, significantly enhance safety and efficiency, enabling predictive maintenance and minimizing downtime.

At the Milpillas Mine, after the crushed ore was hoisted from the underground workings to the surface, an extensive and vital conveyor belt system took over. This system, the backbone of surface material handling, was meticulously designed for the continuous and efficient transport of ore to the processing plant.

The network at Milpillas comprised multiple, interconnected belts, each engineered to handle significant tonnages and often traversing substantial distances. These belts were robust, built with multiple plies for strength and wear resistance, and supported by a series of idlers. Transfer points were crucial, allowing ore to seamlessly move from one belt to the next, forming a complex yet highly optimized material flow path. This “truckless” approach significantly reduced operational costs, fuel consumption, and environmental impact compared to traditional truck haulage.

Key design considerations for the Milpillas conveyor system had focused on maximizing system availability, minimizing wear on components, and facilitating easy maintenance to ensure uninterrupted operation. Advanced control systems, including variable speed drives and material tracking, were employed to optimize belt loading, conserve energy, and provide real-time data on ore flow and quality, all contributing to the overall efficiency of the mine's surface operations.

Original photos courtesy of Veronica Santoyo |

|

| Viewed: |

528 Time(s) |

|

| Description: |

MAIN HOIST ENGINE AT MILPILLAS

Siemag Tecberg, a global leader in shaft hoisting technology, supplied the critical hoist machinery for the main hoist shaft at the Milpillas Mine. The installed hoist equipment was capable of handling significant payloads and operating at impressive speeds, often exceeding 15m/s with capacities up to 60 tons per cycle, depending on the mine's requirements and depth. The installation of such a sophisticated hoist at Milpillas involved a comprehensive process, from initial design and engineering tailored to the mine's unique geology and production targets, to manufacturing, on-site assembly, and rigorous commissioning. At the Milpillas Mine the hoist was tower mounted. Given the scale and depth of the main production shaft at Milpillas, a multi-rope friction hoist (Koepe winder) was installed. This hoist-in-head-frame layout, with its deflecting sheaves, optimized space and distributed the load across multiple ropes, thereby enhancing safety. The overall layout was meticulously planned to ensure seamless integration with the mine's material handling and ventilation systems.

Original photos courtesy of Lopez Hernandez |

|

| Viewed: |

531 Time(s) |

|

| Description: |

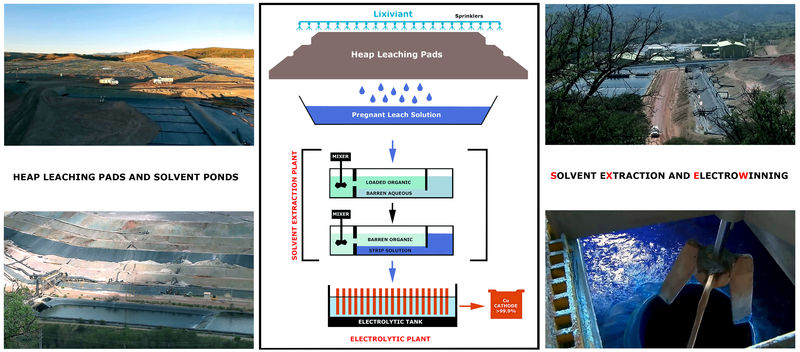

COPPER RECOVER AND COPPER RICH SOLUTION

The images on the left showcase the heap leach pads, equipped with a sprinkler system, and the associated collection ponds containing the leached Copper solution. In the center, a simplified diagram illustrates the Copper extraction process. The upper photo on the right displays the solvent extraction plant (left) and the electrolytic plant (right). Finally, the bottom right-hand photo captures a Copper-rich solution just before it enters the second phase (stripping) at the solvent extraction plant – notice the stirrer assembly.

The heart of the hydrometallurgical process at Milpillas was heap leaching. On specially constructed, impermeable pads, the crushed ore was irrigated with a dilute sulfuric acid solution, known as the lixiviant. As the acid solution percolated through the ore pile, it selectively dissolved the Copper minerals, forming a Copper-rich solution called the pregnant leach solution (PLS). The efficiency of this stage depended on several factors, including the permeability of the ore heap, the concentration of the acid, and the contact time between the lixiviant and the Copper minerals. The Milpillas mine specifically targeted soluble Copper minerals, making heap leaching an ideal and cost-effective method for their extraction.

Following the leaching process, the pregnant leach solution, now laden with dissolved Copper, was directed to the solvent extraction (SX) plant. Solvent extraction is a purification and concentration step. In this stage, the PLS is mixed with an organic based solvent (i.e., alkyl Salicylaldoximes), which have a strong affinity for Copper ions. The Copper ions transfer from the aqueous PLS to the organic phase, leaving behind impurities in the aqueous phase now called the raffinate. This process effectively separates Copper from other undesirable elements that might have been leached from the ore. After the Copper is loaded into the organic solvent, the loaded organic phase is then stripped with a strong sulfuric acid solution, which reverses the process, transferring the concentrated Copper ions back into an aqueous solution. This resulting highly purified and concentrated Copper solution is known as the electrolyte. The final electrolytic cells then deposited high-purity Copper onto cathodes, a process that relied on a consistent and clean electrolyte composition to achieve "Grade A cathodic Copper."

Original photos courtesy of Jose Vazquez, diagram by Silvia. |

|

| Viewed: |

531 Time(s) |

|

| Description: |

INSIDE THE ELECTROWINNING PLANT

The top photo shows the electrolytic cells during insertion of cathode plates. The middle photo shows the Copper clad cathode plates being removed from the tank for processing, and the bottom photo shows the tank charged with new blank cathode plates.

The plant included the use of permanent stainless steel cathodes. Unlike older methods that required “starter sheets” of Copper, these permanent cathodes reduced labor and operational complexities. The Copper was deposited directly onto these blanks, and then mechanically stripped off as high-purity cathode sheets.

Outokumpu's cell designs incorporated polymer concrete cells, known for their durability and chemical resistance in the acidic electrolyte environment. A double-contact bus bar system was a characteristic feature, ensuring efficient current distribution and minimizing energy losses. Ventilation hoods were fitted for effective mist control to capture sulphuric acid mist generated during electrolysis to improve worker safety and reduce environmental emissions.

Furthermore, the plant used advanced automation for handling and stripping the Copper cathodes. This included automated cathode pulling cranes that lift the entire cell hoods and then the loaded cathodes for washing and stripping. The emphasis was on maintaining precise control over electrolyte flow, temperature, and current density to optimize Copper deposition, achieve LME (London Metal Exchange) Grade A purity, and prevent issues like dendrite formation.

The rapid expansion to 65,000 tons of Copper cathode by 2008 further underscored the plant's success and the efficiency of its design and operations. This increased capacity demonstrated the flexibility and scalability inherent in the SX-EW process, allowing for quick responses to market demands and maximizing the economic potential of the Milpillas ore body. The partnership between Outokumpu Technology, with its deep expertise in metallurgical solutions, and Industrias Peñoles, a significant player in the Mexican mining landscape, was crucial. This collaboration brought together world-class engineering and local operational knowledge, creating a facility that not only met but exceeded expectations. The Milpillas plant truly epitomizes the advancements in sustainable and efficient Copper production that defined the early 21st century.

Original photos courtesy of Ofelia Noyola |

|

| Viewed: |

525 Time(s) |

|

| Description: |

COPPER CATHODE PROCESSING

The journey of Copper from electrolyte to a marketable product culminates in the crucial post-electrowinning phase at the Copper cathode plant. Once the electrowinning cycle was complete, the cells yielded crude Copper cathodes – substantial Copper sheets adhering to reusable stainless steel blanks. The initial, highly mechanized step involved the precise removal of these Copper sheets. Automated stripping machines were employed, designed to efficiently peel the deposited Copper from the inert cathode blanks without damaging either the valuable Copper or the blanks, which were immediately returned to the electrolytic cells for reuse.

After separation, these raw Copper sheets, often referred to as full plates, underwent further refinement. They were then conveyed to a trimming station where hydraulic shears or guillotines cut them to precise, standardized dimensions. This sizing ensured uniformity for subsequent handling, packaging, and adherence to customer specifications. While the electrowinning process itself yielded high-purity Copper, a final surface preparation, usually a thorough rinse with demineralized water, was performed to remove any residual electrolyte, dust, or minor surface impurities. This step ensured the pristine quality and appearance of the final product.

Finally, the prepared Copper cathodes were systematically stacked. They were typically stacked horizontally, often on pallets, in precise numbers – commonly 20 to 50 sheets per stack, depending on the cathode thickness and desired bundle weight. These stacks were then bound with steel strapping, ready for weighing, quality inspection, and dispatch to various industries worldwide.

To transform these cathodes into various Copper products, they were subjected to further processing at facilities exterior to the mine. This usually involved melting the cathodes in a shaft furnace, followed by continuous casting and rolling. The molten Copper was cast into a suitable form, often a thick slab or strip, which was then passed through a series of rolling mills. This mechanical working reduced the thickness of the Copper, enhances its grain structure, and improved its mechanical properties; ultimately producing high-quality Copper sheets of the desired gauge and finish, maintaining the exceptional 99.99% purity.

Original photos courtesy of Salvador Rivera |

|

| Viewed: |

528 Time(s) |

|

| Description: |

REFINED COPPER CATHODES

Like most modern Copper mines, Milpillas produced large, high-purity "Grade A cathodic Copper" sheets, adhering to LME (London Metal Exchange) and ATSM standards (American Society for Testing and Materials). These sheets commonly measured around 914mm x 914mm (36" x 36") with a thickness of about 12mm (0.5") and bundled in stacks of 50 sheets as shown in photograph. Each sheet weighed approximately 90 kilograms (198 pounds), making them efficient to handle and transport in industrial quantities.

Grade “A” cathodic Copper sheets, are the purest form of commercially traded Copper, typically boasting a minimum purity of 99.99%. The physical properties of Grade “A” cathodic Copper sheets are directly linked to their high purity. They exhibit exceptional electrical conductivity, second only to silver, making them indispensable for electrical wiring, cables, and electronic components. They also possess high thermal conductivity, crucial for heat exchangers and refrigeration. Furthermore, these sheets are highly malleable and ductile, allowing them to be easily shaped, drawn into fine wires, or rolled into thin sheets without fracturing. They are also corrosion-resistant, particularly in atmospheric and aqueous environments, due to the formation of a protective oxide layer. Their uniform rectangular shape and consistent composition simplify industrial handling and processing.

Original photos courtesy of Dagoberto Flores |

|

| Viewed: |

529 Time(s) |

|

| Description: |

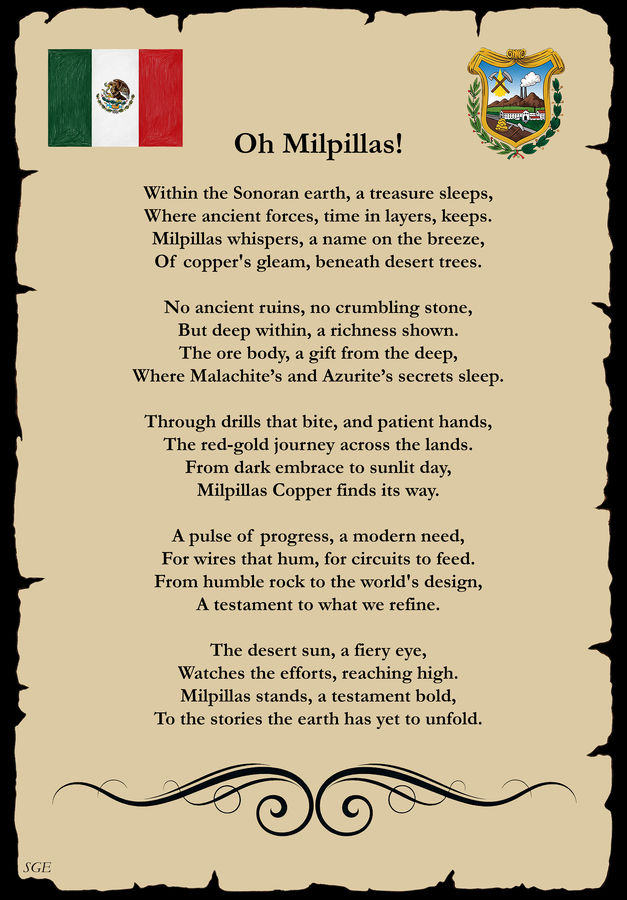

AN ODE TO MILPILLAS – OH MILPILLAS!

The Milpillas Mine stands as a powerful testament to the remarkable capabilities and unwavering dedication of the Mexican people and their industry. Far more than just a mining operation, it represents the successful creation of a world-class facility, born from a blend of innovative engineering, strategic vision, and sheer determination.

From the outset, the project faced formidable challenges. The Milpillas deposit, rich in high-grade Copper, was hidden beneath a significant overburden of water-saturated alluvial sediments, demanding sophisticated and persistent efforts to access and extract the valuable ore. This wasn't a simple excavation; it required a deep understanding of complex geology and the implementation of cutting-edge underground mining techniques. The Mexican teams, led by companies like Industrias Peñoles, rose to this challenge with exceptional skill and ingenuity.

Their ingenuity was evident in every phase of the mine's development and operation. Overcoming severe flooding issues, they deployed efficient pumping systems that not only kept the project on track but also demonstrated a commitment to environmental responsibility. Furthermore, the continuous optimization of operational efficiency dramatically improved equipment availability and reduced maintenance downtime. This meticulous attention to detail, leading to increased safety for personnel and significant cost reductions, showcases a culture of continuous improvement and operational excellence.

Beyond the technical prowess, Milpillas also embodies a forward-thinking approach to sustainability. The integration of a large solar thermal plant to power the mine, replacing diesel and significantly reducing carbon emissions, positioned Milpillas as a global reference in renewable energy use within the mining sector. This demonstrated a profound commitment to responsible resource management and a proactive stance on environmental stewardship.

The mine’s success wasn't just measured in Copper cathodes produced, but also in the world-renowned mineral specimens it yielded, attracting global attention to Mexico's rich mineralogical heritage. This dual achievement — economic output and scientific contribution — underscores the comprehensive excellence achieved at Milpillas.

In essence, the Milpillas Mine is a vibrant example of how Mexican industry, through its skilled workforce, visionary leadership, and embrace of advanced technology, can transform complex geological challenges into a highly efficient, sustainable, and globally recognized mining enterprise. It stands as a proud symbol of the Mexican people, their diligence and their industrial achievement on the world stage. |

|

| Viewed: |

528 Time(s) |

|

| Description: |

FINAL THOUGHTS AND FUTURE DIRECTIONS

Well this concludes, for now, my FMF journey into the heart of the Milpillas mine, a place that, for many, remains a fascinating enigma. What I presented was a mere synopsis, a fleeting glimpse into what truly constituted the day-to-day operations of a world-class mining endeavor like Milpillas. The discussions, diagrams and photographs presented for your enjoyment were carefully crafted with broad brush strokes, designed to give you a sense of the vast canvas that was Milpillas. Indeed, it felt at times as if so much was discussed, yet so little was actually revealed, leaving many questions lingering.

That deliberate restraint was, in part, due to the nature of most online forums. There are, quite simply, many aspects of the daily operation of mines like Milpillas, their remarkable people, and their unique practices that are not entirely appropriate for most online public forums in the modern era. The nuances, the challenges, the triumphs, and the sheer scale of human ingenuity at play demand a more considered and comprehensive presentation.

And therein lies the future. My core goal is to delve deeper into the stories of the mines I love, uncovering the finer details and finally sharing the untold narratives that simply couldn't be fully explored before. This means a deep dive into every facet of these captivating sites, from their hidden complexities and geological intricacies to the profound, often overlooked human experiences that shaped them. I'll illuminate the intersection of industry, environment, and individual lives, revealing the full, nuanced tapestry of these extraordinary places.

THE PROMISE

To truly bring this world to life, I've amassed hundreds of photographs – a visual chronicle born from my passion for science and people. Many have undergone meticulous digital rendering, ensuring they seamlessly complement the narratives. This is a labor of love, designed to transport you directly into the heart of the mines I've come to cherish.

Far from a mere catalogue or a dry academic thesis, this work offers a meticulously researched exploration, vibrantly illuminated by high-quality photographs, renderings, and drawings from my personal collection and travels. It celebrates the inherent beauty and intricate formations of these geological treasures. Beyond their aesthetic allure, I delve into the compelling stories behind the specimens in my collection, unveiling the history and operational characteristics of the mines that yielded them. These narratives are further enriched by the personalities who shaped these endeavors and the societies that nurtured their existence across the globe.

Adding a truly unique dimension, select minerals are paired with evocative poetry, digitally enhanced and restored 19th-century watercolour illustrations of their original mines, and watercolour-like depictions of the specimens themselves. Each element harmoniously bridges the gap between scientific appreciation and artistic interpretation.

THE AUDIENCE

This work isn't just for mineral enthusiasts; it's an invitation to explore the captivating world of minerals for everyone. While teachers will find it rich with deep insights and collectors a useful resource, my real aim is to engage everyday individuals who appreciate beauty, industry, and honesty.

For the curious mind eager to explore the often-hidden world of minerals, this resource is your guide. Delve into their scientific foundations, diverse industrial applications, fascinating origins, and significant societal impact. Writers and journalists, in particular, will find it an indispensable tool for in-depth research.

So enjoy - Naõ he pobre, senaõ o que se tem por pobre ..! |

|

| Viewed: |

525 Time(s) |

|

|

|