| View previous topic :: View next topic |

| Author |

Message |

Roger Warin

Joined: 23 Jan 2013

Posts: 1246

|

Posted: Jan 09, 2014 00:57 Post subject: A hardness gemologist tool Posted: Jan 09, 2014 00:57 Post subject: A hardness gemologist tool |

|

|

Hi,

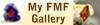

Here is a gemologist tool that seems rare.

A crown carries 6 stones to test Mohs hardness.

The values are: 6.3/4 7 7.1/2 8 8.1/2 9

What are these stones?

What is the name of the tool?

Roger.

PS: It’s seems to me that 9 is a sapphire and 7.1/2 a garnet.

| Description: |

Hardness tool

5.5 cm

with 6 stones |

|

| Viewed: |

19334 Time(s) |

|

| Description: |

|

| Viewed: |

19328 Time(s) |

|

|

|

| Back to top |

|

|

gemlover

Joined: 31 Dec 2008

Posts: 211

Location: Easley, SC

|

Posted: Jan 09, 2014 02:08 Post subject: Re: a hardness gemologist tool Posted: Jan 09, 2014 02:08 Post subject: Re: a hardness gemologist tool |

|

|

We used wheels like this in my mineralogy course in college (50 years ago). I have not seen one since then. Thanks for the memories. BTW, a gemologist would not use this, as we don't scratch the cut gems.

However a mineralogist could.

John

_________________

John

John Atwell Rasmussen, Ph.D.. AJP

Geologist and Gemologist |

|

| Back to top |

|

|

vicen

Joined: 25 Aug 2011

Posts: 20

Location: Edinburgh

|

Posted: Jan 09, 2014 03:47 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 03:47 Post subject: Re: A hardness gemologist tool |

|

|

Quite an interesting tool. Is it still in the market? Tá

_________________

Geological Conservator/Preparator

Natural Sciences Department

National Museums Scotland

242 West Granton Road

Edinburgh EH5 1JA |

|

| Back to top |

|

|

Roger Warin

Joined: 23 Jan 2013

Posts: 1246

|

Posted: Jan 09, 2014 04:54 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 04:54 Post subject: Re: A hardness gemologist tool |

|

|

Oh no! This wheel was in an old collection.

Its profile is similar to that of a trapiche wheel used in crushing rocks.

Roger.

|

|

| Back to top |

|

|

Mark Ost

Joined: 18 Mar 2013

Posts: 516

Location: Virginia Beach

|

Posted: Jan 09, 2014 06:55 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 06:55 Post subject: Re: A hardness gemologist tool |

|

|

| Quite remarkable. Interesting that the gradations go to fractional units.

|

|

| Back to top |

|

|

Riccardo Modanesi

Joined: 07 Nov 2011

Posts: 631

Location: Milano

|

Posted: Jan 09, 2014 08:42 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 08:42 Post subject: Re: A hardness gemologist tool |

|

|

Hi to everybody!

Do you think this instrument is safe to be used on cut stones? Some 30 or 40 years ago there was an instrument called sclerometer, which was a pool of "points" made of the 10 Mohs scale terms (talc, gypsum, chalcite etc.). It wasw abandoned because it was said too dangerous for cut stones; in particular the diamond point is dangerous even for a cut diamond itself! If it is useful for rough stones (i.e. crystals), it's ok, but I doubt about its usefulness on cut stones!

Greetings from Italy by Riccardo.

_________________

Hi! I'm a collector of minerals since 1973 and a gemmologist. On Summer I always visit mines and quarries all over Europe looking for minerals! Ok, there is time to tell you much much more! Greetings from Italy by Riccardo. |

|

| Back to top |

|

|

Roger Warin

Joined: 23 Jan 2013

Posts: 1246

|

Posted: Jan 09, 2014 09:26 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 09:26 Post subject: Re: A hardness gemologist tool |

|

|

Hello,

It is likely that this is a hand held instrument for a geologist on the ground. It could of course be used before cutting of a gemstone. Currently, this is an obsolete antique.

Roger.

|

|

| Back to top |

|

|

vic rzonca

Joined: 18 Nov 2008

Posts: 820

Location: MA

|

Posted: Jan 09, 2014 09:55 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 09:55 Post subject: Re: A hardness gemologist tool |

|

|

Roger, what would be the modern replacement for this tool? Perhaps the go-no go hardness of a Mohs 5 implement is all that's needed? It is an elegant object.

Vic

|

|

| Back to top |

|

|

Mark Ost

Joined: 18 Mar 2013

Posts: 516

Location: Virginia Beach

|

Posted: Jan 09, 2014 11:42 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 11:42 Post subject: Re: A hardness gemologist tool |

|

|

| A guess metal point sets are the new analog of this tool. I have a boxed set that is graduated on the whole number mohs scale. No fractional reading.

|

|

| Back to top |

|

|

Mark Ost

Joined: 18 Mar 2013

Posts: 516

Location: Virginia Beach

|

Posted: Jan 09, 2014 11:51 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 11:51 Post subject: Re: A hardness gemologist tool |

|

|

Here is what I use

| Description: |

|

| Viewed: |

19090 Time(s) |

|

|

|

| Back to top |

|

|

vic rzonca

Joined: 18 Nov 2008

Posts: 820

Location: MA

|

Posted: Jan 09, 2014 11:52 Post subject: Re: A hardness gemologist tool Posted: Jan 09, 2014 11:52 Post subject: Re: A hardness gemologist tool |

|

|

| Great Mark, thanks. Gonna git me a set.

|

|

| Back to top |

|

|

cascaillou

Joined: 27 Nov 2011

Posts: 263

|

Posted: Jan 16, 2014 19:17 Post subject: Re: A hardness gemologist tool Posted: Jan 16, 2014 19:17 Post subject: Re: A hardness gemologist tool |

|

|

I wouldn't scratch a cut stone. Actually, it's best to avoid any potentially destructive testing (i.e. hardness, streak, acid) when dealing with cut stones. On the other hand, if all classical gemology non-destructive tests have already been implemented, and I'm left with only two or three possibilities for the mineral identity, and if those could be easily separated by their substantial hardness difference (like 2 or more Mohs graduations), then I might consider it. Even then, I wouldn't scratch the cut stone, but rather scratch a flat smooth polished plate of known hardness with the gemstone (do not use rough unpolished pieces of the mohs scale minerals).

But that's risky too as the stone might chip if its hardness is equal or inferior to the polished plate. Therefore one should start with a low hardness plate (meaning lower than the hardness of your softer candidate for the stone identity) and work up progressively, applying little pressure during scratching. As the plates get harder, scratching these with the stone gets less easy, and if at some point you can't get a scratch then do not try applying more pressure and just stop the hardness testing at this point. Anyway, at that point you already have an approximative idea of what the hardness is anyway (let's consider you might have an error of 1.5 Mohs graduation in the worth case) , which might be sufficient to orientate your choice between the 2 or 3 possibilities left for your mineral identity.

Of course always make sure that the scratch on the test plate is actually a scratch, not a streak, you can make sure by:

rubbing it vigorously with your moist finger tip (unlike a streak, a scratch shouldn't disappear when doing so), and then scratch it perpendicularly with your finger nail (a scratch is a groove so it should catch your nail a bit)

That's why I think hardness points aren't a good choice (as you'll likely end up scratching your stone), I'd rather use polished hardness plates (it's also risky, but if all goes well you can get an approximative idea of the stone hardness without damaging it).

However, if you want to test uncut minerals, then it's best to have both points and plates (to get more accurate hardness result, meaning 0.5 mohs graduation accuracy, you need to know both what the stone can scratch and what the stone can't be scratched with)

|

|

| Back to top |

|

|

|