| View previous topic :: View next topic |

| Author |

Message |

Adrian

Joined: 25 Dec 2010

Posts: 2

Location: Spain

|

Posted: Dec 25, 2010 13:15 Post subject: Gluing rock to rock for art display Posted: Dec 25, 2010 13:15 Post subject: Gluing rock to rock for art display |

|

|

I am working on a composite sculpture in which I need to permanently glue together a large number of 10-35 lb river stones. I would like to know if any of you know what industrial glue would be most suitable for bonding stone-to stone or stone to cured cement for perpetuity.

All suggestions will be greatly appreciated.

|

|

| Back to top |

|

|

Turbo

Joined: 30 Sep 2009

Posts: 260

Location: Delaware

|

Posted: Dec 25, 2010 21:18 Post subject: Re: Gluing rock to rock for art display Posted: Dec 25, 2010 21:18 Post subject: Re: Gluing rock to rock for art display |

|

|

| Some epoxy resins may be suitable. There's also something called "mastic" and other silicone sealants (I do not know any product names) tend to stick well to rock, but may not be very weight bearing.

|

|

| Back to top |

|

|

marvsT/Nminerals

Joined: 06 Nov 2008

Posts: 68

Location: Juda, Wisconsin

|

Posted: Dec 26, 2010 00:11 Post subject: Re: Gluing rock to rock for art display Posted: Dec 26, 2010 00:11 Post subject: Re: Gluing rock to rock for art display |

|

|

I would go down to my local hardware store and check with one of their consultants. It sounds as if you are going to need bulk quantities for such a project. Most of those on this forum collect minerals rather than rocks and rarely use adhesives such as you consider.

_________________

Member: Badger Lapidary and Geological Society

Great things can be found in small packages! |

|

| Back to top |

|

|

nurbo

Joined: 23 Sep 2008

Posts: 457

Location: Lancashire

|

Posted: Dec 26, 2010 02:31 Post subject: Re: Gluing rock to rock for art display Posted: Dec 26, 2010 02:31 Post subject: Re: Gluing rock to rock for art display |

|

|

Hello,

I have 12 years experience of building outdoor stonework, personally I wouldnt consider any kind of glue, mastic or silicone based products, eventually the glue will come unstuck (Despite manufacturer claims to the contrary).might take a year or two but it will fail.

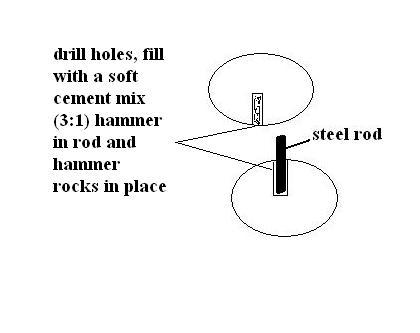

Whenever Ive done anything involving sculptural stonework of the manner you suggest Ive drilled holes in the stones and used pieces of steel cut to size that penetrate both stones and held it together that way, filling the holes with cement prior to inserting the steel rods to prevent them from wobbling. Where I live the temperature differential over a year can be 40+ degrees, from +30 to - 10, there is no glue that I would trust to work over that range of temperature for long,. Ive added an extremely simplistic drawing to demonstrate what I mean. I hope this helps..

b

| Description: |

| simple sketch of method for bonding exterior stones. |

|

| Viewed: |

12164 Time(s) |

|

|

|

| Back to top |

|

|

Adrian

Joined: 25 Dec 2010

Posts: 2

Location: Spain

|

Posted: Dec 26, 2010 09:20 Post subject: I should have said Gluing CONCRETE to CONCRETE for an art display Posted: Dec 26, 2010 09:20 Post subject: I should have said Gluing CONCRETE to CONCRETE for an art display |

|

|

Thanks to all of you for your feedback.

Nurbo--- you're right. I myself worked in construction for as long as you have and I totally agree with everything you mentioned.

I'm now including a photo of something similar to the piece I'm creating. What you see on the photo has an iron armature under the cement. It was applied in several layers, but every layer covered the entire armature from one end to the other.

The piece I'm creating which will be very similar but it isn't possible for me to apply the cement coating over its entire metal skeleton so I'll have to apply it to each individual piece separately. Once all of them have been coated to the desired thickness I will have to weld all the metal rods that run through their interior, which will be sticking out 1 inch.

When I do the entire piece will be solidly held together but the problem I'll have is that there will be a 2 inch gap between each cement piece at every spot where it got welded. The end product needs to look "seamless" like the pieces on the photo so a coating of cement will need to be applied to fill in the 2 inch gap to hide the metal rod.

I will be applying wet cement over cured cement and so, over time, being that what I'm building will be out in the open exposed the weather elements all year long I'm afraid I will get cracks at every welded spot where the new and old come into contact.

Even if I create a roughed-edged surface at the end of each cement piece to have more a bite when the new cement is applied, I'm afraid that plain cement, even with fiber glass hair and all the fortifying additives I can put in it won't be strong enough to create a lasting bond that won't crack at some point.

When gluing two pieces of glass to each other there are "super glues" such as Araldit that will make the bonded area even stronger than the glass being glued, so I guess what I'm looking for is a bonding compound hat will bring the same results.

I've been reading about "marine epoxy" which is very strong but concrete is very porous so I'm not sure it will work with it. I'm thinking that a cement mixture formulated for maximum bonding might be the way to go. Perhaps both concrete parts to be joined can also be coated with a bonding agent before applying the mix to the gap

Thanks again for your reply. Please let me know what you think.

Adrian

| Description: |

|

| Viewed: |

12176 Time(s) |

|

|

|

| Back to top |

|

|

|